Company name: Ansteel Machinery Development Private Enterprise Machinery Factory

Anshan Shuangxing Galvanizing Co., Ltd

Contact: Shen Taisheng

WhatsApp:+8615382137795

Tel.: 0412-8812449

Q Q:1481198998

Postal code: 114000

Email: bestgalvanizing@163.com

Website: www.agxinguo.com

Plant site: Ansteel plant

Office address: No. 111, Ximinsheng Road, Tiexi District, Anshan, Liaoning

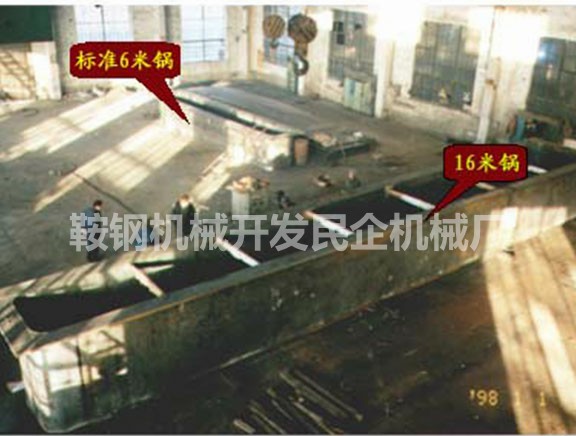

Galvanizing pot is the key equipment for hot galvanizing of steel strip. Its function is to melt zinc ingot and realize the galvanizing process of steel strip in the production process. Therefore, the supply of zinc and heat taken away by the steel strip must be guaranteed to maintain a stable galvanizing temperature and the total amount of zinc.

Reduce the combustion intensity of the combustion system of the zinc boiler body, reduce the heat transfer of the zinc boiler to the zinc liquid, keep the temperature of the zinc liquid above 420 ℃, avoid a large amount of solidification of the zinc liquid, and provide guarantee for temperature rise and rapid re production. This method is only suitable for the large interval section where production stops due to insufficient workload in hot dip galvanizing production. Galvanized pot

Galvanized pot

If it is a temporary or short interval production interval, the insulation temperature should be increased to facilitate the temperature rise in a short time, so as to reach the zinc liquid temperature required for normal zinc dipping at a fast speed. For example, if the working temperature of zinc liquid in production is set at 450 ℃, the temperature of zinc liquid during insulation will be controlled above 430 ℃.

Hot galvanizing is an effective method of metal corrosion prevention. After hot-dip galvanizing, the corrosion resistance of steel materials can be increased by 11-28 times, and the service life can reach more than 25 years. Hot dip galvanizing pot is a key equipment of galvanizing process. Its function is to coat molten zinc on the surface of the plated parts, so as to form a surface coating and improve the corrosion resistance of steel parts. However, molten zinc is highly corrosive to steel materials, which leads to short service life of hot-dip galvanizing pot, and the service life of hot-dip galvanizing pot will directly affect the output and production cost of galvanized products.