Company name: Ansteel Machinery Development Private Enterprise Machinery Factory

Anshan Shuangxing Galvanizing Co., Ltd

Contact: Shen Taisheng

WhatsApp:+8615382137795

Tel.: 0412-8812449

Q Q:1481198998

Postal code: 114000

Email: bestgalvanizing@163.com

Website: www.agxinguo.com

Plant site: Ansteel plant

Office address: No. 111, Ximinsheng Road, Tiexi District, Anshan, Liaoning

1. Tank substrate treatment

The pickling tank, solvent tank and cleaning tank shall be resistant to the corrosion of acid or chlorinated hinge. These grooves are generally made of steel or concrete, and then the corrosion resistant material layer is laid on the substrate surface of the inner wall of the groove. The surface layer of the base material shall be treated in advance, which will directly affect the quality of the anti-corrosion project.

The tank body shall be constructed with cement mortar concrete, which shall be firm and solid, and shall be free from sanding, shelling, cracks, pits, etc. The surface flatness and slope shall meet the design requirements and the requirements of the code for construction and acceptance of building anti-corrosion works. The internal and external corners shall be made into circular arc or inclined plane. Before the anti-corrosion coating is applied, the floating ash and dirt on the substrate surface shall be removed and dried to a depth of 20mm, and the moisture content shall not be greater than 6%. The treated base material should be covered with clean fabric to prevent contamination.

The surface of the steel tank shall be treated before the anti-corrosion coating is applied. The welding slag, burr, rust, oil stain, dust, etc. shall be removed to make the surface smooth and clean with metallic luster. The better method is sand blasting.

The pipes, sleeves, embedded parts or reserved holes passing through the anti-corrosion layer shall be embedded in advance or left in the base.

2. Structure of anti-corrosion coating

Anti corrosion coating includes surface layer and isolation layer. The surface layer (including the bonding layer with the isolation layer) not only directly contacts the corrosion medium, but also bears the mechanical action. During the pretreatment of hot-dip galvanizing, steel structures often collide and scrape the anti-corrosion surface, so the firmness and wear resistance of the surface are particularly important. The isolation layer (including the leveling layer on the surface of the substrate) is mainly used to prevent the corrosion liquid penetrated by the surface layer from eroding the substrate.

Common materials for surface course: when the tank body is subject to large impact load, acid resistant bricks, thick acid resistant block stones (granite, diabase, etc.), and water glass concrete with reinforcement mesh are usually used. When the tank body is only subjected to general impact load, acid resistant ceramic plate, water glass concrete, asphalt mortar, glass fiber reinforced plastic, asphalt or resin impregnated brick can be used. PVC or polypropylene sheet. The acid resistance of wood is not very good, but the price is low, and the construction, maintenance and replacement are very convenient. Therefore, it is also commonly used as the surface material, but the corresponding isolation layer requirements are high, for example, the glass fiber reinforced plastic with a thickness of more than 2mm is used.

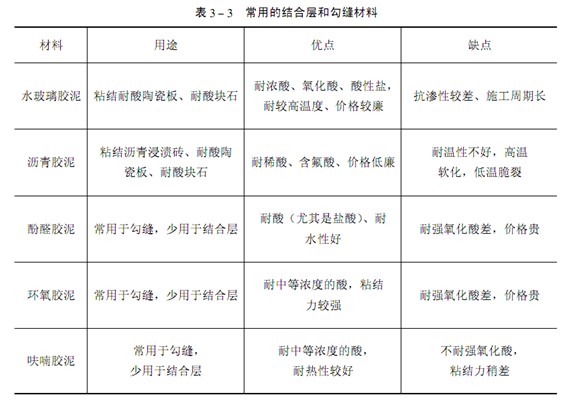

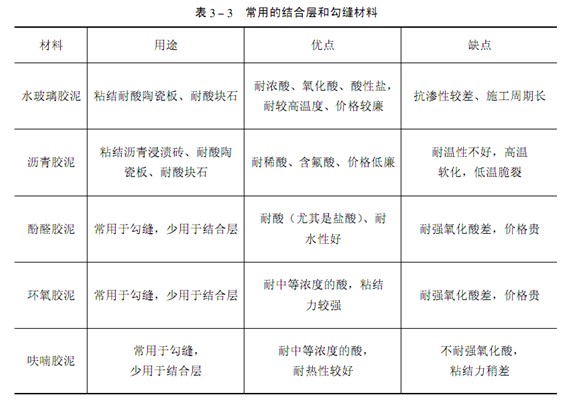

See Table 3-3 for common bonding layer and pointing materials, and Table 3-4 for common isolating layer materials.

3. Heating of pickling tank and solvent tank

The heating of the pickling tank depends on the acid used. The acid pickling efficiency of sulfuric acid is the highest at about 65 ℃, and the steam is usually passed into the lead coil placed in the acid tank to heat the acid solution. If hydrochloric acid is used, heating is generally not required except in cold weather.

The solvent tank can be heated by titanium or stainless steel coil with steam or hot water. In recent years, the heat exchanger made of polytetrafluoroethylene (commonly known as plastic king) thin wall thin tube with hot water has been used to heat the solvent, and the effect is also very good.