Company name: Ansteel Machinery Development Private Enterprise Machinery Factory

Anshan Shuangxing Galvanizing Co., Ltd

Contact: Shen Taisheng

WhatsApp:+8615382137795

Tel.: 0412-8812449

Q Q:1481198998

Postal code: 114000

Email: bestgalvanizing@163.com

Website: www.agxinguo.com

Plant site: Ansteel plant

Office address: No. 111, Ximinsheng Road, Tiexi District, Anshan, Liaoning

Section I Zinc Extraction Pump and Slag Trap

When the zinc pot is overhauled or replaced, the zinc pump can be used to quickly extract the zinc liquid from the zinc pot. Generally, the zinc pump can extract 1~2t zinc liquid per minute, as shown in Figure 5-1. When using the zinc pump, the following procedures must be followed: use a crane to lift the zinc pump vertically, stay 10cm above the zinc bath surface, and use the radiant heat of zinc liquid to heat the zinc pump for 3~5min; Then slowly immerse the zinc pump body about 10cm below the zinc bath surface. After the zinc pump is heated for 3~5min, turn the pump shaft manually. If the pump shaft can rotate freely, start the zinc pump immediately (pay attention to whether the rotation direction of the pump shaft is correct) to avoid blocking the zinc pump due to excessive growth of iron zinc alloy in the zinc pump. The zinc temperature shall be checked regularly during zinc extraction.

The nozzle of the zinc flow pipe of the zinc extraction pump shall be kept a small distance higher than the zinc liquid level in the zinc ingot mold or the standby zinc pot to reduce the impact, splash and oxidation of the zinc liquid and the damage to the zinc ingot mold or the standby zinc pot. After zinc extraction, the zinc pump must continue to run for a short period of time before and after leaving the remaining zinc liquid, so as to remove all the remaining zinc in the pump.

After the zinc pump is lifted from the zinc pot, some steel plate spacers must be vertically inserted into the remaining zinc liquid at the bottom of the zinc pot, so that the zinc can be divided into several large zinc ingots after solidification; Before solidification of each zinc ingot, a solid steel lifting ring shall be inserted in advance. The lifting ring is usually bent into an Ω shape with thick steel bars, which is convenient for taking out and lifting these large zinc ingots.

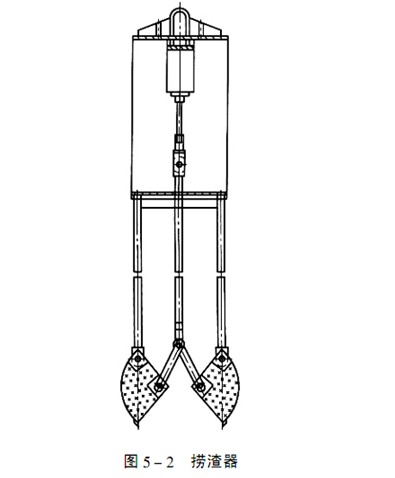

The zinc slag in the zinc pot shall be removed regularly. The zinc slag is generally salvaged with slag catcher. There are many types of slag catchers, and the grab type slag catcher is a common one, as shown in Figure 5-2. The grab type slag catcher has a movable grab. There are many small holes on the steel plate of the grab to allow the zinc liquid to flow out freely, while the zinc slag is left in the bucket. The slag catcher is suspended above the zinc pot by the crane in the workshop. For safety reasons, the opening and closing of the grab is generally pneumatically controlled, and the cylinder drives the connecting rod to control the opening and closing of the grab.

The steel parts immersed in the zinc bath when the zinc pump and slag catcher are working shall be made of materials resistant to the corrosion of zinc liquid.

Waste acid and wastewater treatment plant and smoke and ash removal equipment are also important auxiliary devices and equipment in hot galvanizing plant, but they are often classified as environmental protection devices and equipment according to their functions. This book will introduce relevant contents in relevant chapters.