Company name: Ansteel Machinery Development Private Enterprise Machinery Factory

Anshan Shuangxing Galvanizing Co., Ltd

Contact: Shen Taisheng

WhatsApp:+8615382137795

Tel.: 0412-8812449

Q Q:1481198998

Postal code: 114000

Email: bestgalvanizing@163.com

Website: www.agxinguo.com

Plant site: Ansteel plant

Office address: No. 111, Ximinsheng Road, Tiexi District, Anshan, Liaoning

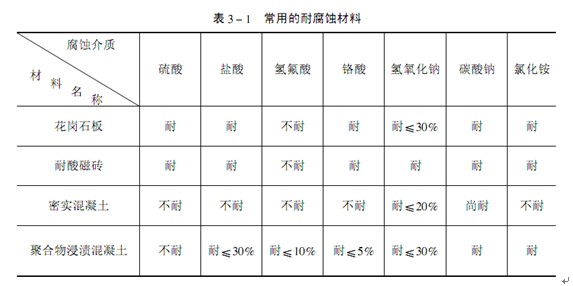

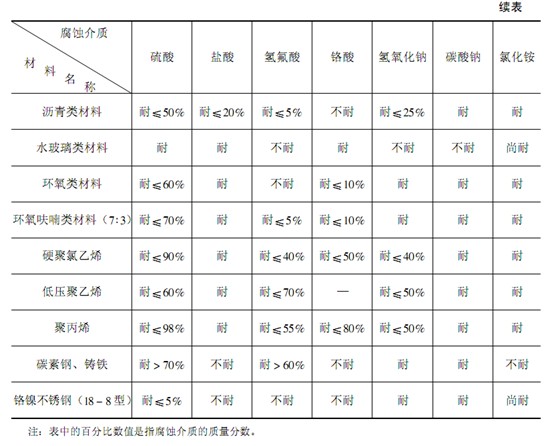

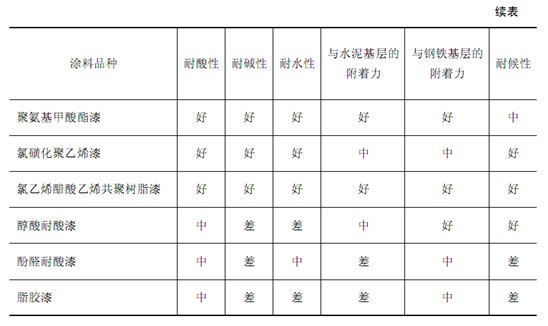

Section I Common Corrosion Resistant Materials and Coatings

The pretreatment process tank of the hot galvanizing workshop includes degreasing tank, pickling tank, solvent tank and cleaning tank for water washing after degreasing and pickling. Degreasing solution, acid solution and water after flushing degrease or pickling of workpieces are corrosive, so these tanks and related ground, pipeline and drainage facilities need to use various building anti-corrosion materials and coatings. There are many varieties of architectural anti-corrosion materials and coatings; The corrosion resistance of various anti-corrosion materials to acid, alkali, salt and other media is different. Cement materials have good alkali resistance, but poor acid resistance; Bituminous materials have good resistance to dilute acid and alkali, but are not resistant to concentrated acid, concentrated alkali and organic solvents; Water glass materials have excellent acid resistance, but not alkali resistance; Epoxy materials have good comprehensive properties of acid, alkali and salt resistance, but are not resistant to strong oxidizing acids. According to the law of thermodynamics, a material is relatively stable under some environmental actions, while it will be damaged and deteriorated under other environmental actions. Therefore, when selecting materials, efforts should be made to make the best use of everything.

See Table 3-1 and Table 3-2 for commonly used corrosion resistant materials and coatings for pre-treatment process tank of hot galvanizing workshop and related facilities.